| Price | Negotiate |

| MOQ | Negotiate |

| Delivery Time | 8 - 15 days after payment |

| Brand | Uchi |

| Place of Origin | Dongguan China |

| Certification | CE / SGS / ISO9001 |

| Model Number | Surge Protection Device parts |

| Packaging Details | Negotiate / Export package |

| Payment Terms | T/T, L/C, Western Union |

| Supply Ability | 50000 pieces per month |

| Place of Origin | Dongguan China | Shell material | PBT material |

| Packaging Details | Negotiate / Export package | Degree of protection | IP20 |

| Model Number | Surge Protection Device parts | Supply Ability | 50000 pieces per month |

| Certification | CE / SGS / ISO9001 | MOQ | Negotiate |

| Brand Name | Uchi | Payment Terms | T/T, L/C, Western Union |

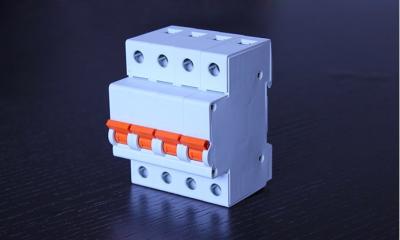

| Brand | Uchi | Pole number | 4P |

| Price | Negotiate | Delivery Time | 8 - 15 days after payment |

| Accessories production | Full set of accessories | Minimum Order Quantity | Negotiate |

| Application | Power Protection | Certificate | CE / ROHS / ISO9001 |

Applications:

Techwin

SCB

thunder

protector

surge

citel

SPD

backup

protector

4P

In

low

voltage

power

systems,

surge

back-up

protector

(SCB)

is

an

external

disconnector

used

in

series

with

surge

protector

(SPD),

suitable

for

AC

50/60hz,

230v-400v

range

of

TT,

TN

and

other

power

supply

systems,

the

product

power

frequency

action

current

is

less

than

3A,

(8/20

s

impulse

current

can

pass

through

120kA).

All

the

performance

indexes

of

products

exceed

miniature

circuit

breakers

and

fuses,

making

them

the

best

choice

for

SPD

backup

protection.

A,When

there

is

a

transient

overvoltage

in

the

power

supply

line,

the

SPD

conduction

will

have

a

meltdown

short

circuit,

which

will

cause

power

tripping

and

serious

fire

accidents.

The

installation

of

SCB

is

to

quickly

disconnect

the

circuit

when

the

SPD

has

a

transient

overvoltage

short

circuit,

thus

avoiding

the

serious

consequences

of

SPD

meltdown

burning

fire!

B,When

there

is

lightning

current

in

SCB,

the

external

disconnector

will

not

mistrip

due

to

lightning

current,

so

that

the

electrical

equipment

protection

is

always

in

an

effective

protection

state.

Anti-overcurrent

and

overheating

protection

components

The

anti-overcurrent

components

have

self-recovery

fuses,

current

fuses,

and

resistors,

and

the

anti-overheat

protection

and

overheat

detection

components

have

temperature

fuse

and

temperature

fuse.

A

resettable

fuse

is

a

positive

temperature

coefficient

thermistor.

When

the

current

flowing

through

it

is

less

than

its

holding

current

(low

temperature),

its

resistance

is

very

small;

when

the

current

flowing

through

it

exceeds

its

trigger

current

(temperature

Increase),

its

resistance

value

increases

sharply,

thereby

blocking

the

continuous

intrusion

of

lightning

current

or

the

freewheeling

of

the

circuit,

and

it

can

recover

by

itself

after

the

temperature

drops.

However,

due

to

thermal

inertia,

the

reaction

speed

is

very

slow,

generally

in

seconds

(the

greater

the

current

or

the

higher

the

temperature,

the

faster

the

reaction).

Self-recovery

fuses

can

be

used

to

replace

current

fuses,

eliminating

the

trouble

of

frequent

replacement.

Thermal

fuse

and

thermal

fuse

are

a

kind

of

temperature

switch

components,

which

are

short-circuited

during

normal

operation.

When

the

temperature

is

higher

than

the

disconnection

temperature,

the

switch

will

be

disconnected

(unrecoverable).

They

are

often

used

for

overheating

protection

and

overheating

detection.

Shell

material:

Using

international

brand

nylon

material

and

international

brand

PBT

material,

the

bending

strength

is

in

accordance

with

GB/T9341-2008,

and

the

impact

strength

of

the

simply

supported

beam

is

notched

and

unnotched.

Comply

with

GB/T1043.1-2008,

flame

retardancy

complies

with

GB/T2408-2008,

excellent

electrical

insulation

performance,

and

strong

consistency

of

product

surface

technology.

Stamping:

It

is

made

of

high-precision

copper,

and

the

screws

and

locking

sleeves

are

electroplated

after

heat

treatment.

The

advantage

is

that

the

product

is

not

easy

to

slip,

the

salt

spray

test

can

reach

72

hours,

and

the

plugging

force

is

moderate.

Elaboration

1. It is recommended that the maximum flow of SPD Imax: 10-60KA.

2. It is recommended that SPD be used in an environment of -40℃ to +100℃.

3. 1P, 2P, 3P, 4P can be distributed according to demand to meet various needs.

4.35mm

guide

rail

design

is

convenient

for

subsequent

installation.