As

the

world's

leading

packaging

prepress

application,

DPM

series

of

prepress

productivity

tools

has

evolved

from

Yintech’s

10

years

of

accumulated

research

and

development

experience

in

the

graphic

arts.

DPM

series offers

professional

trapping

tools,

specialized

step

&

repeat

functions

for

packaging

as

well

as

a

series

of

editing

tools

enabling

prepress

operators

to

boost

efficiency

and

produce

higher

quality

work.

|

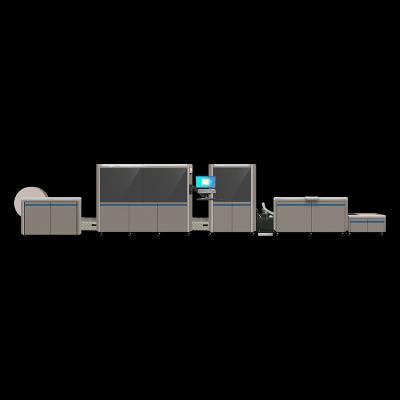

Model

|

DMP540

|

|

Printing

method

|

Monochrome

duplex

/

Dual-color

/

CMYK

duplex

|

|

Resolution

|

600x600dpi/2bit,

600x1200dpi/2bit

(maximum)

|

|

Maximum

printing

speed

|

100

m/min

|

|

Overprint

accuracy

of

front

and

back

|

±0.3mm

|

|

Sprinklers

|

On-demand

piezoelectric

sprinklers

for

industrial

use

|

|

Ink

type

|

water-based

pigment

ink,

dye

ink

|

|

Drying

method

|

infrared

drying

|

|

Operation

interface

|

Visual

operation

interface

|

|

Maximum

media

width

|

560mm

|

|

Maximum

printing

width

|

540mm

|

|

Paper

weight

|

45-165

g/m²

|

|

Paper

type

|

Offset

paper,

newspaper,

inkjet

coated

paper

digital

printing

paper,

etc.

|

|

Maximum

roll

diameter

|

1.27

meters

|

|

Mechanical

platform

|

380Vac,

15KW

Max

|

|

Infrared

drying

|

380Vac,

1-35KW

Max

|

|

Digital

control

system

|

220Vac,

6KW

Max

|

|

Temperature

range

|

22.5-27.5°C,

best

working

temperature

25°C

|

|

Humidity

range

|

40-70%RH,

best

working

humidity

50-60%RH

|

Convenient

and

easy

to

use

•

Print

immediately

after

power-on,

without

wasting

paper

for

start

up.

•

The

output

software

can

do

continuous

printing

and

inserting

printing,

which

is

convenient

for

arranging

small

jobs

to

be

printed

at

any

time,

without

stopping

the

machine

and

wasting

paper,

improving

efficiency

and

saving

production

costs.

•

By

the

concept

of

system

engineering,

the

whole

machine

has

a

high

degree

of

automation

and

better

overall

interoperability,

which

greatly

reduces

the

number

of

operators,

the

difficulty

of

personnel

management

and

the

continuous

increase

of

labor

costs.

Low

consumption,

high

efficiency,

stable

and

reliable

operation.

Low

production

cost

•

The

maximum

power

of

the

inkjet

system

is

11.5KW,

the

maximum

power

of

the

cutting

system

is

22KW,

and

the

maximum

power

of

the

entire

system

is

33.5KW.

The

actual

production

is

about

12KW.

•

The

entire

system

is

energy-saving

and

environmentally

friendly,

with

low

global

power

consumption,

low

overall

operating

costs,

and

production

quality

that

meets

users'

current

business

needs,

helping

users

obtain

faster

return

on

investment.

Exclusive

technology

•

Unique

anti-broken

line

technology

and

ink

supply

technology

that

can

guarantee

the

entire

printing

process

without

breaking

line.

•

The

ink

developed

by

independent

technology

has

better

printing

adaptability,

low

power

consumption

drying

performance

and

paper

adaptability.

Scalability

•

Can

be

upgraded

to

two-color

printer.

•

A

variety

of

cutting

programs

are

under

development,

and

third-party

cutting

programs

are

supported.

More

Affordable

Inkjet

POD

Solution

in

the

World!

•

Market

approved

drop-on-demand

industrial

inkjet

head

technology

•

Total

roll-to-sheet

print-on-demand

inkjet

print

solution

•

Short-run

mono-color

duplex

or

dual-color

duplex

book

and

periodical

printing

•

Flexibledeployment

of

structure,

easily

expand

to

dual-color

duplex

or

spot

color

•

Sales

price

competitivity

as

lower

as

offset

press

Have

you

or

your

customers

been

struggling

the

pain

points

in

traditional

offset

book

and

periodical

pringting?

•

Huge

waste

of

inventory

/

repertory

/

stock

•

Environmental

impact

of

waste

and

costly

chemical

treatment

•

Long-term

press

ready

time

•

Smelly,

noisy

and

dirty

workshop

harmful

to

worker's

health

•

Increasingly

cost

of

human

power

Today,

you

are

having

the

right

solution

ever

before

from

YINTECH,

most

affordable

POD

solution!

Core

Technologies

•

Inkjet

printhead

control

•

Circulating

ink

supplying

control

•

Automatic

printhead

self-clean

system

•

Fast-speed

paralleling

RIP

•

Variable

data

processing

•

Special

multiple

grade-level

FM

screening

for

inkjet

Productivity

•

Practical

printing

speed:

100m/min

•

Power-on

to

ready

time:

<20

minutes

•

Daily

maintenance

time:

<20

minutes

•

Daily

running

time:

>20

hours

•

63,000

A4

prints

per

hour

on

average

speed

at

85

m/min

•

Average

sales:

lower

than

laser

and

approaching

to

offset

•

Competitive

balance:

2,000-3,000

copies

comparing

to

offset